Machine Health Monitoring

Predict & Prevent 70+ Machine Faults months in advance with AlertOpsTM

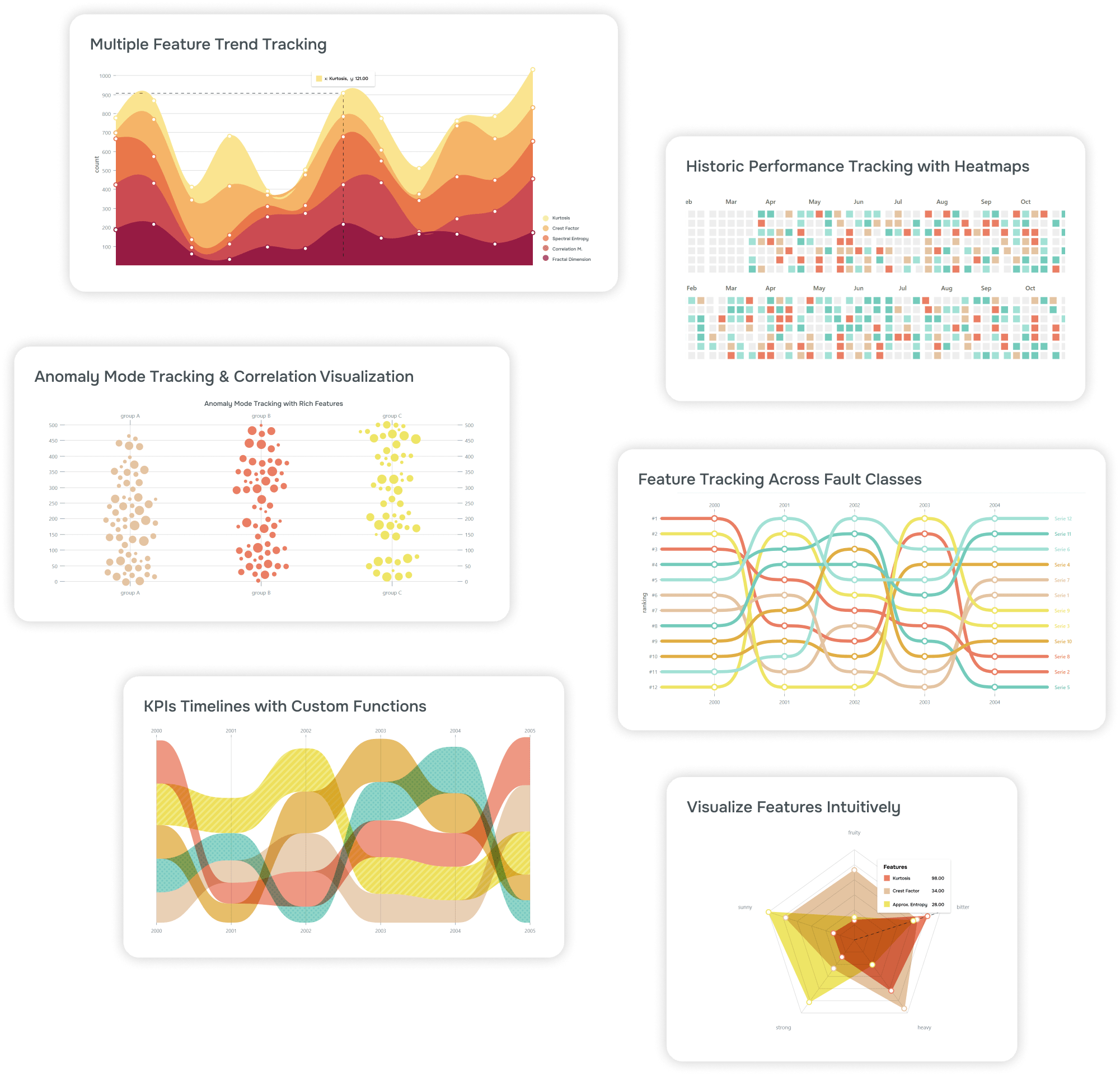

FormFour Provides you with automatic, continuous, & comparative tracking abstracted from millions of data points to derive Condition Indicators of Machine's Health using Vibration, Temperature, Speed, Current, Lubrication & contextual O&M data

Predict & Prevent 70+ Machine Faults months in advance with AlertOpsTM

Maximize your Factory Performance, Process Quality, Capacity & Reliability

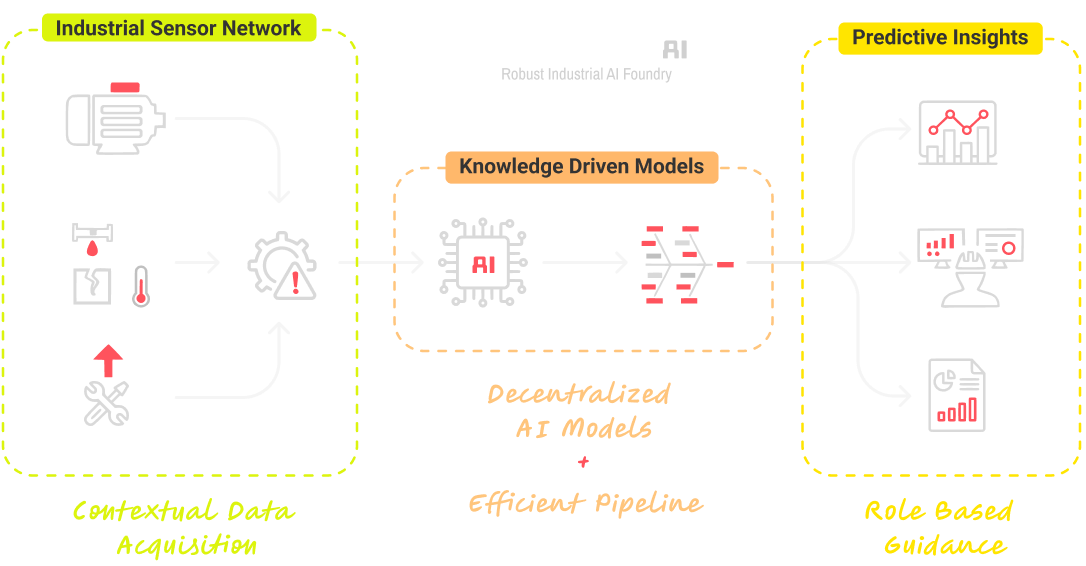

Get multi-modal context based data from Vibration, Temperature, Pressure, Speed, Current & other O&M contextual metrics all in one place!

Robust Knowledge Driven Edge Models enable Rich feature extraction, trend tracking & multi-class classifications enabling highly efficient data pipelines

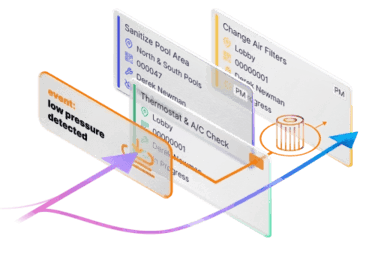

Get Actionable Role-based insights & suggestions for O&M teams enabling rapid response, Improved reliability, high uptime & lower costs

FormFour, founded by Shreeneet Rathi, a Design Engineer and IIT Bombay graduate, specializes in optimizing manufacturing operations and maintenance for O&M teams. Our agile team focuses on the Mining, Steel, Chemical, Pharmaceutical, Textile, and Sheet Metal Forming industries, though we cater to the reliability needs of any rotating or reciprocating equipment.

We provide a comprehensive, end-to-end platform that includes data acquisition devices and custom-built, knowledge-driven predictive models. Our expertise extends to designing, developing, and deploying custom role-based prescriptive models that deliver actionable insights, empowering onsite O&M teams to make informed decisions swiftly.

Our goal is to optimize factory operations at both the machine and process levels, particularly for MSMEs in India.

Our offerings include:

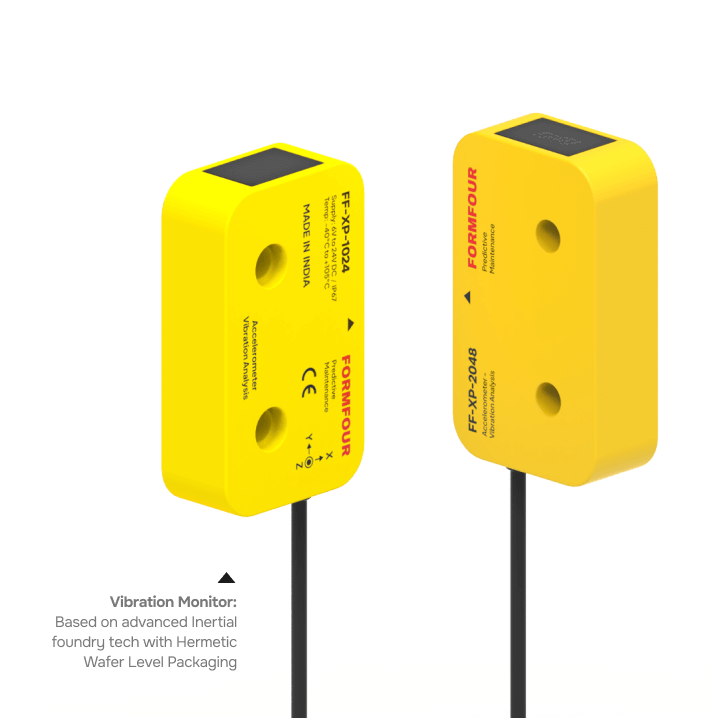

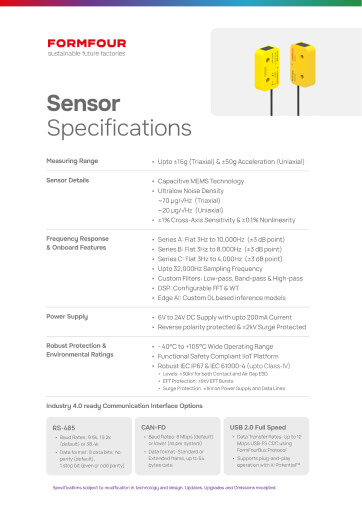

- Sensors

- Gateways

- Customized System Modeling

- Fine-Tuning Predictive Maintenance Models

- Strategic Consultation for Predictive and Condition-Based Maintenance

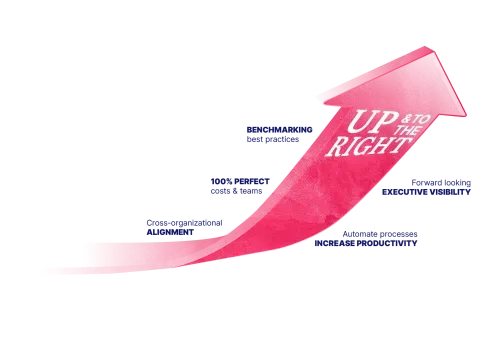

Predictive Maintenance is often a viable financial investment for teams & operations of micro to large scales. The primary value generated by PdM is improved uptime, OEE, MTBF, MTTR, and asset life; reduced waste, emissions, and downtime; 24x7 monitoring of machines & processes; reduced MRO costs by more than 24%; and reliable production routines.

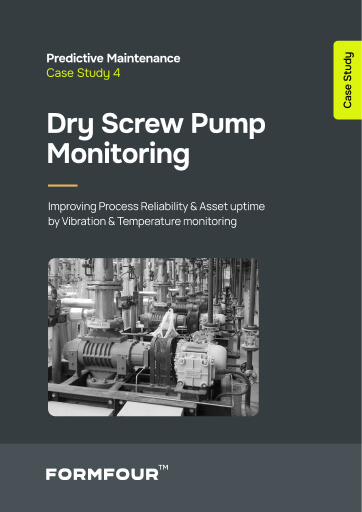

By utilizing FormFour's AlertOps and the PredictX vibration sensor, your maintenance team gains critical insights through predictive alerts, potential fault classifications, and prescriptive recommendations regarding your machine or process performance. This proactive approach allows you to address faults before breakdowns, increasing operational reliability and reducing preventative maintenance costs.

At FormFour, our mission is to make the benefits of Predictive Maintenance (PdM) and Condition-Based Monitoring (CbM) accessible to manufacturing facilities of all sizes, from micro-enterprises to large-scale operations. We place a special emphasis on MSMEs in India, offering highly competitive pricing with a typical return on investment (RoI) period of less than 3 months, and up to 18x RoI within the first year.

The typical cost per asset for OEMs starts at around INR 42,000. The overall investment varies depending on the specifics of the PdM/CbM program, which may include hardware costs, engineering simulations, infrastructure setup, and data analytics services.

With a team of Data Scientists from IIT Bombay, we leverage cutting-edge R&D that is not only advanced but also tailored to meet the specific needs and challenges of the Indian manufacturing sector. Our solutions are designed to be both efficient and effective, ensuring they are perfectly suited to the demands of this market.

We help improve:

- Overall Equipment Efficiency

- Mean Time Between Failures

- Mean Time To Repair

- Overall Unplanned Downtime

- Minimize overall Energy Consumption

- Minimize Cost of Inventory

- Increase Capacity Utilization

At FormFour, our vision is to enable sustainable future factories across India, from micro to large-scale industries. By reducing waste in energy, materials, and time, we strive to foster sustainability at scale, contributing to a more efficient and eco-friendly manufacturing ecosystem.